|

|

|

|

Identifying Engines & Parts |

|

Abbreviations:

DEW

=

Detroit

Engine

Works.

WMC =

Wadsworth

Manufacturing

Co. DMCSC =

Detroit

Motor

Car

Supply

Co.

CEC =

Columbia

Engine

Co.

MSBC =

Michigan Steel

Boat

Co.

DBC =

Detroit

Boat

Co. SMPC =

Standard

|

|

The information on this page was collected from original

Detroit Engine Works, Detroit Motor Car Supply Co. & related

companies manuals, parts bulletins, patents, ad literature,

etc... That has been scanned and posted on this website and is believed to be

accurate. If you have original

literature, documentations, photos that you

would like to donate so that other collectors and restores may view this

information. please e-mail me.

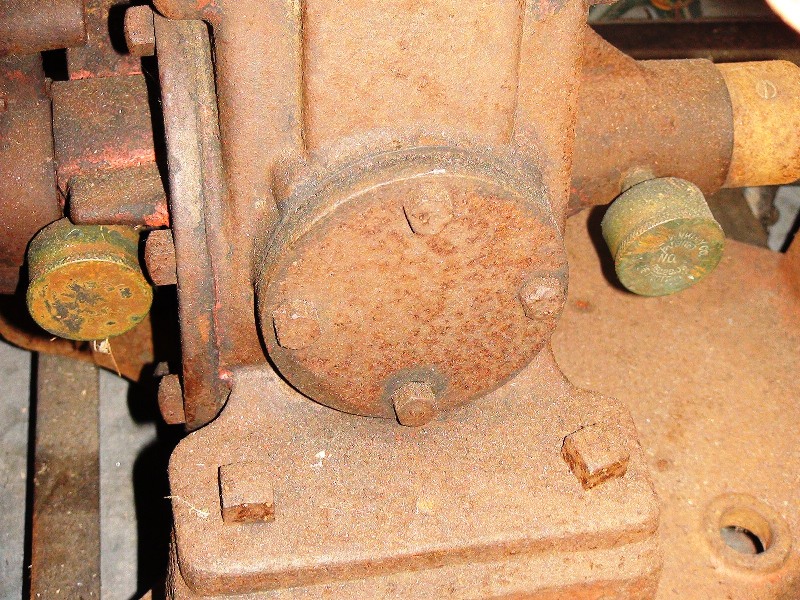

mazak@rocketmail.com ____________________________________________________________________________________________ There are a number of companies

that manufactured engines stationary and marine that appear to look just

like or very similar to the DEW two cycle style engines produced back in

the early 1900's. The information below will explain what some of the

differences are on the engines manufactured or

sold by DEW, DMCSC, CEC, MSBC, DBC, CPMC, MEC, BGEC, PIW. CPMC

stationary engines also have unique features such as the tapered

ends of the crank shaft with nuts used to hold the flywheels on . Most

of the DEW style stationary engines used gib keys to secure the

flywheels. Air

intake & governor arm on the CPMC engines are cast different then DEW styles. (See photos

CPMC section). These unique features make this companies engine easy to

distinguish from other DEW style engines.

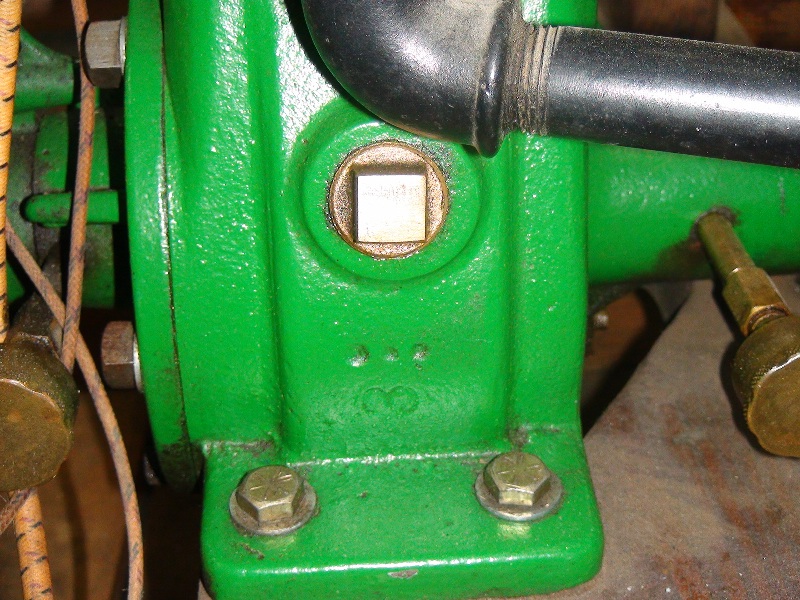

1st early style

Inspection hole 1900 - 1907

Also if you have a Detroit type stationary engine with

two flywheels that has no name tag it will be difficult to figure out who

the manufacture is unless it is a Middleditch or Bessemer these engines

are fairly easy to identify from a DEW or DMCSC by looking at the fuel

injector, exhaust manifold, engine base, cylinder shape, etc..

____________________________________________________________________________________________ |

|

Peterson Automatic Fuel

Feeder-Injector |

|

The early two piece Automatic fuel feeder-injector (patent # 926,892) was designed by John Peterson and Frederick O. Peterson patented on July 6, 1909 manufactured by Ben J. MiddleDitch for DEW. Application for this patent was filed on Feb 24, 1908 and it appears that this fuel injector was produced a number of years before being patented in 1909. A DEW engine catalog dated 1907,1908 shows this same fuel feeder-injector with a ribbed fuel reservoir cap, see photo's below. Original literature shows that this early style fuel reservoir-injector was used on DEW, DMCSC stationary and Marine engines. At this time I do not have proof that this fuel feeder was used on other brand name engines but there is a good possibility that is was. Sources = (1906-1908 DEW Catalog), (U.S. Patent # 926,892), (1909 DEW Catalog), (Part List Bulletin No. III Jan 1st 1912), (Parts List Bulletin No. III part 3 Nov 1st 1914), (1915 DEW Catalog), (Information embossed on Peterson fuel feeders).

(patent #

926,892)

|

|

Barthel Automatic Fuel Feeder-

Injector

|

|

The one piece fuel feeder-Injector (patent # 1,026,425) was designed by Frederick Barthel

assignor to Frederick Wadsworth who owned & managed Detroit Engine

Works. The patent application for this fuel feeder was filed on Jan 7,

1911 but they were being manufactured by DEW sometime before 1911 and then patented May 14, 1912. There were 3

different versions of this one piece fuel feeder/Injector produced. All three

versions were patented under the same patent number. They are

listed below in the order in which they were produced.

Sources=

(U.S,Patent

# 1,026,425), (Part List Bulletin

No. III Jan 1st 1912), (1913 DMCSC Catalog), (Parts List Bulletin No. III part 3 Nov 1st 1914), (Parts List Bulletin No. III

Jan, 1st 1915), (1915 DEW Catalog).

Literature shows the first style being used on DEW, DMCSC stationary

engines. I'm sure that all three fuel feeder versions were

probably used on other make and/or style engines.

_____________________________________________________________________________________________________________

3rd version 1911-12

This 3rd version fuel feeder had a new improved top cap which was

rounded and set higher allowing for the 1/4" pressure/vaccum tube inside

the reservoir to set higher above the fuel level. The new cap is

referred to by many collectors as the acorn top fuel feeder. This

modification was also introduced

around the 1911-1912 time period and was the last fuel feeder produced

by DEW until the company went out of business in 1920. Literature shows

that this style fuel feeder injector was used on

all DEW, DMCSC stationary engines with two flywheels and on some of the DEW, DMCSC single

flywheel stationary and marine engines.

_____________________________________________________________________________________________________________

Detroit natural gas air intake valve.

______________________________________________________________________________________________________________

Some of the 3rd style fuel feeders had a primer cup valve that

was mounted to the top of the acorn cap or the side of the reservoir, This allowed you to prime the fuel reservoir after the engine had

set for a period of time and the fuel had evaporated or seeped down to the fuel tank. This

primer cup valve would

save you the trouble of having to find a wrench and remove the reservoir cap every

time. Injector tubes are made from standard 1/8" copper tubing with

1/16" inner

|

|

|

|

|

|

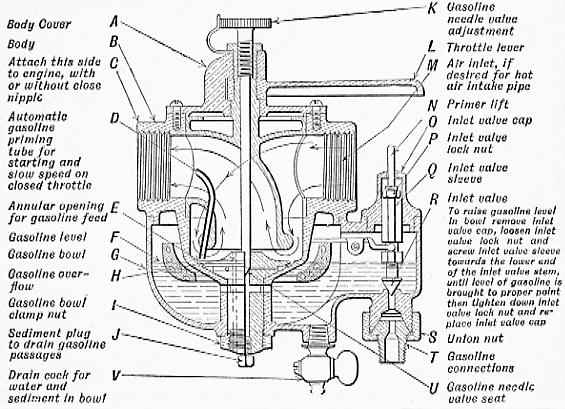

This carburetor was built by the PlanHard Manufacturing Co. Used on DEW, DMCSC, CEC

marine engines.

|

Lavigne Mfg. Co. also made a mixer that looks real close to the ones used on the Detroit engines. |

|

|

|

|

|

Water Injection |

|

In the early 1900's most engine companies who manufactured kerosene type

engines used water injection. The literature below is from the Detroit Motor Car Supply Company catalog

about their Sandow engine

explaining why they use water injection. DEW, DMCSC, CEC all used water

injection on their larger

engines.

|

| Drip Feed Lubricator's |

|

Some time later a single lubricator

with two drip lines was introduced that did the same work of the two

single drip oilers but with only one oil reservoir. Some antique engine enthusiast

believe that the lubricators on the Detroit engines are sealed units and

oil is injected into the engine by pressure from the crankcase. I have

found no original literature or avertisements to support this theory. I

have original Detroit manuals, catalogs, Sales literature, advetisements

and none of them say anything about the Detroit having a pressure feed

oiling system and believe me if it did have this they would be using it

in their advertising to try and boost thier sales. The manuals states

that the lubrication system is drip feed and grease cups for the main

bearings. These types of oilers have a check ball below each drip sight

glass to keep air pressure and oil from blowing back into the oil

reservoir. Manuals do state that the lower connecting rod bearing is

positive feed lubrication but not from air pressure but from centrifical

force using a oil slinger ring mounted on the crankshaft. See photos

below.

|

| DEW & Sandow Stationary Governor Linkages |

Early Style Governor Linkage 1907-1912

|

| Magneto's, Alternator's, Buzz coil's |

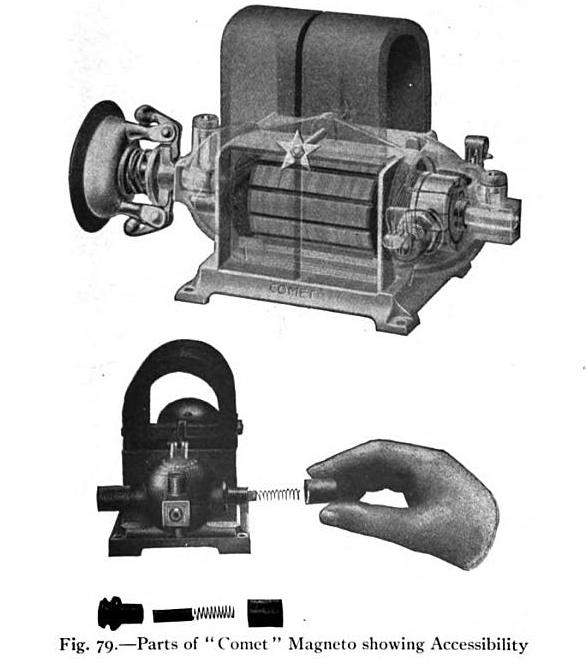

In the factory DEW parts catalog they call this a Comet Magneto sold for $9.00 new. This is actually a small alternator with a rubber friction wheel that you would drive against the flywheel, some times called a battery saver. You would start the engine using a dry cell battery and buzz coil. Once the engine was running good and steady you would flip a switch disconnecting the battery and connecting the alternator. Alternator would now supply alternating current (AC voltage) to the buzz coil. The buzz coil contact points last much longer using (AC) alternating current rather then (DC) direct current. For more information on ignition see DEW wiring diagram above. |

| Kingston Magneto |

Kingston magneto could be purchased as option for the big twin cylinder Detroit engines.

|

| Stationary Buzz Coil |

|

This is an identical reproduction of

the old Detroit buzz coils, even has the electronics potted in tar just like the

old original buzz coils. John Regan makes these Detroit style buzz coils & also reproduces the

model T ford style buzz coils. See website link for more

info. http://www.funprojects.com/

_________________________________________________________________________________________ |

|

Marine & Stationary Engine Info |

|

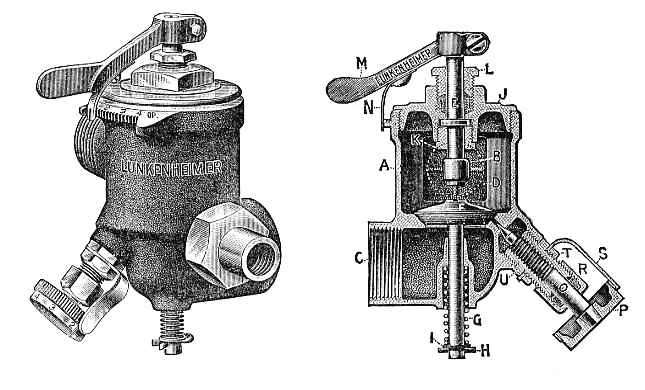

Research shows that DEW, DMCSC, CEC marine engines were

offered in many different configurations over the years. An assortment

of carburetors and mixers manufactured by different companies, DEW,

Schebler, Lunkenheimer, Essex, Krice, Williams, Lavigne are just a few that are known

to have been used. Ben J. Middleditch manufactured the first

fuel injection systems that were used on some of these marine engines. Then DEW

manufactured three different styles of fuel feeder-injectors in the

proceeding years after.

* The 8hp was the only stationary engine

that had bolt on internal counter balance weights for the crankshaft.*

Source = (Parts

List Bulletin No. 111 Jan 1st 1912), (Parts

List Bulletin No. 300 March 1st 1916).

DEW & DMCSC (Stationary Engines with two flywheels) Some time between 1913 and 1914

a new cylinder style change was made on 5 hp all

the way up to 20 hp. Exhaust port changed from direct pipe thread into

the cylinder to bolt on flange type

manifold elbow. The bottom water inlet also changed to bolt on style

flange. The position of water port on top of cylinder changed by 90 degree's.

The place were the oil line screwed into the cylinder moved from the

left side of the cylinder to the right side. The (Lower Con Rod) oil

line that screwed into the crank case on the right was moved to the left

side. The 4hp and under engines still used the old style cylinders that

did not have the bolt on flange for the exhaust and lower water inlet. Single drip oiler's or double drip oiler's offered on all single

cylinder engines. These oilers came with check

valves built into them, This kept the crank case pressure from blowing

the oil in the line back into the oiler. One oil line

lubricated the big end of

the connecting rod. The second oil line lubricated the piston and the

small end of the connecting rod. Some of the larger two cylinder

DEW engines did have pressure feed oil systems. A oil pump that was belted to the

crankshaft with multiple oil lines through out the engine. Sources

= (1909

DEW Catalog), (Parts

List Bulletin

No. III Jan 1st 1912), (Part List Bulletin No. III part 3 Nov 1st 1914), (1915 DEW Catalog).

Below are some photo's of various engine tags that might be of interest to some of you collectors. |

| Main Menu |